Thermal foggers, use heat to vaporize a fogging solution and spray it out as a visible fog cloud with a .05–10-micron range particle size. Thermal foggers are equipped with a heat barrel that is preheated to high temperatures using propane, gas, or electricity depending on the type of fogged. When the liquid fogging solution is pumped into the heat barrel it is instantly vaporized. This allows the fogger to produce large count of particles in extremely small size, which all together forms a dense cloud of fog which resembles smoke. Thermal foggers produce smaller particles which means they take longer to fall to the ground. The smaller thermal fog particles are useful if you are spraying for mosquitoes, as the longer the particles are suspended in the air, the more likely they are to contact the mosquitoes. However, the near invisible fog generated by a cold fogger may be better suited for neighborhoods where the highly visible smoke produced by a thermal fogger may cause alarm. Cold foggers are quieter than thermal foggers.

Cold Foggers or Ultra low Volume (ULV) foggers provide a cold fog with particle sizes in the 5-20 micron range. Cold foggers use air pressure to atomize the insecticide and are powered by gasoline, compressed air, or electricity. The lack of heat (and thus the fire risk) makes the ULV fogger safer for indoor use. Both thermal foggers and ULV or cold foggers may be used inside or outside and both can fog water or oil-based products. Sanitizers, disinfectants, mold, and fungi control products are most often applied by cold foggers which allow adjustment of the particle size and provide larger particles used for these applications. Research data indicate ULV fog is best for indoor control of stored product insects (beetles, moths, etc.). The optimum particle size theory plays an important role in the use of ULV fogging equipment for insect control. Droplets of pesticide found to be most effective are those with a small size range allowing them to remain airborne for a considerable length of time and to be carried to the insect by atmospheric transport. Once a droplet reaches an insect, a final requirement is that it impinge (stick) on the insect. Research data indicate that droplets of 5-15 microns (1 micron = 1/25,000 inch) size range best meet those criteria. Larger droplets settle out of the air too rapidly and penetrate cracks and crevices poorly. Smaller droplets tend to deflect around the target insect rather than hitting and impinging on it. Most ULV equipment produce particles in this size range. Large, portable ULV foggers are available for use on ATV’s and other vehicles for fogging large warehouses or outdoor areas. For inside application of large areas, ULV foggers may be permanently installed overhead, thus eliminating the need to transport the fogger throughout the facility. With automatic, overhead, permanently installed, ULV systems, large facilities can be fogged in a short period of time without labor cost.

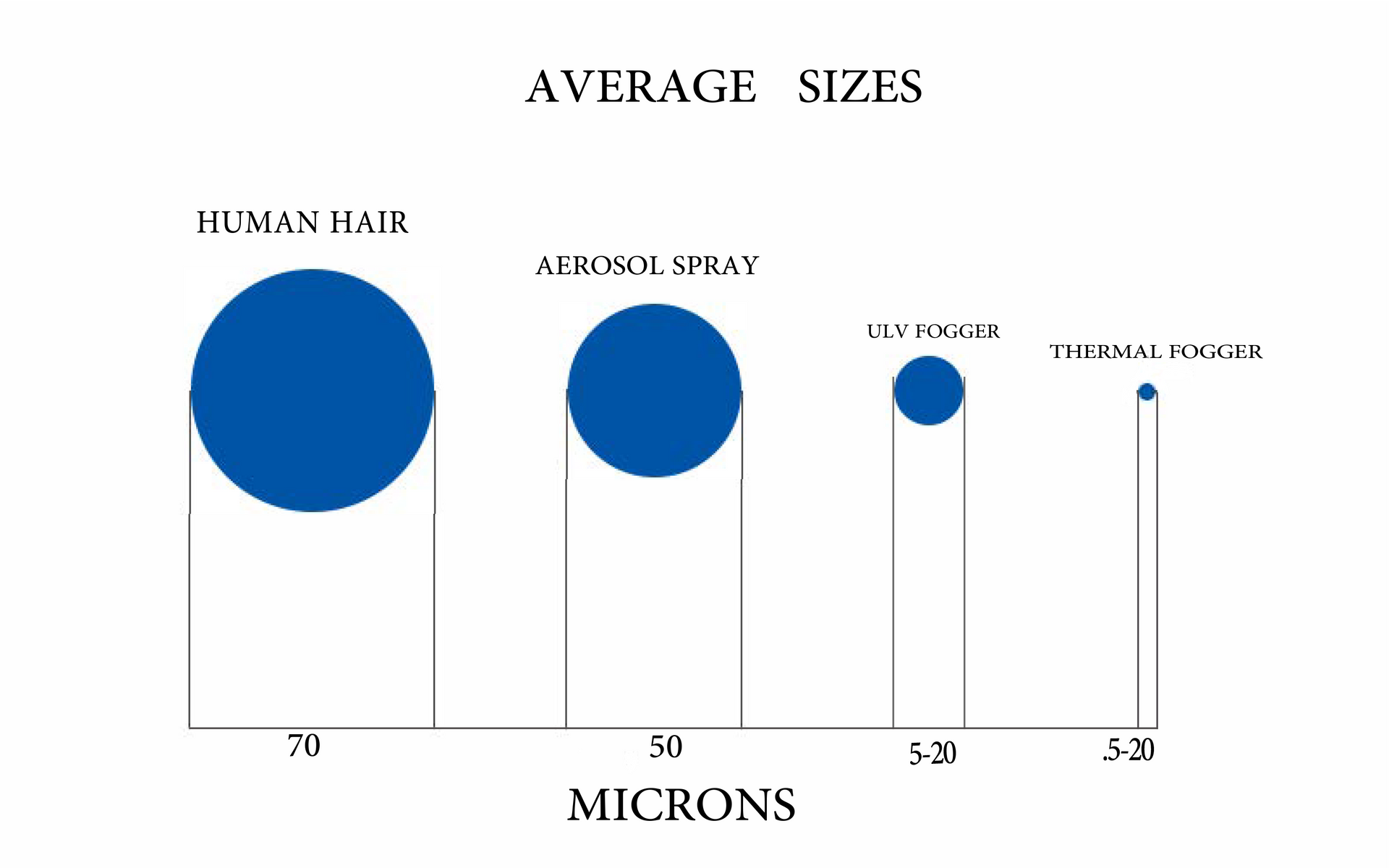

Particle sizes

The particle size produced by thermal and cold foggers will vary based on the model of the fogger. However, thermal foggers generally will produce smaller in size particles, averaging from 0.5-10 micron range, while ULV foggers will output a bit larger in size particles, averaging from 5-30 micron range.The heating technique thermal foggers use allows to produce extremely tiny particles, as small as 0.5 microns, which can penetrate very small areas indoors and outdoors. Insecticide or other solution is vaporized to produce a dense and thick cloud of fog. The fog produced by a thermal fogger is easily visible, which allows to better control the direction of the fog. Different ULV foggers will produce different sized droplets, based on the use of the fogger. While thermal fogger can produce extremely small particles, their size is inconsistent meaning that particles a fogger outputs will range dramatically from 0.5 up to 30 microns in size. ULV foggers at the same time can produce a very consistent particle size and particle size of these foggers can be adjusted by adjusting the flow rate. This is especially useful if you need to fog different areas or use the fogger for various purposes, for example getting rid of molds or unpleasant odors indoors or killing insects and other pests outdoors. ULV foggers also need less diluent, so they can produce more concentrated fogging solutions, which make some type of chemicals cheaper to use.

Uses

The usage of both thermal and ULV foggers is similar in many ways, as both devices are generally foggers or misters and are used to spray out either a water or oil based fogging solutions. Both types of foggers are used in such applications as insect control, odor and mold control in indoor areas, for disinfection, to apply pesticides to plants, getting rid of pests in warehouses and other similar uses. Besides these places, there are other areas, where thermal foggers are better suited than ULV foggers and other way. Thermal foggers have advantage of producing particles in smaller size than ULV foggers and the fog is also easily visible, which makes them better in such applications as:

Mosquito and insect control. Because of small droplets a thermal fogger produce, they are good for mosquito and other smaller insect control. For mosquito control the best droplet size is from 5-20 microns, and most thermal foggers will produce particles in this range. Controlled outdoor fogging. Because fog that a thermal fogger produce is thick and easily visible, you can more easily control the direction of fogging. This will make an outdoor fogging more controlled, because most ULV fogging devices produce hardly visible fog.

Fogging obstructed areas. Because of small particle size, fog produced by a thermal fogger can reach in very small places such as floor gaps, cracks in walls and similar places indoors, or into thick bushes, long grass, high tree tops and other hard to reach outdoor places. ULV foggers in opposite do not use extensive heat in fogging process, so they can be used indoors without fire risks. Also, allow to adjust particle size, so they can be used in more applications than thermal foggers.

ULV foggers are used:

In any indoor place. As mentioned above, ULV foggers use cold fogging techniques, so they are safe to use indoors.

For odor control and disinfection. ULV foggers are often used to disinfectant houses and large warehouses as well as control unpleasant odors in such areas. ULV fogger can be left to work automatically and there isn’t need for a person to operate the fogger all the time as with thermal foggers.To get rid of molds. ULV foggers are also used with special chemicals to get rid of molds in indoor areas. On plants and greenhouses. Because ULV foggers allow to adjust particle size, they can also be used outdoors or in greenhouses to spray different solution on plants.

Indoor and outdoor pest control. ULV foggers are the best pest control method for indoor areas, however, they are also used outdoors, for example to control mosquitoes. Although ULV foggers cannot produce such small particles as thermal foggers, some ULV foggers can produce particles from 5-20 micron range, which is effective for mosquito control.

Insecticide use Rates

Insecticide use rates are regulated by the E.P.A. and use rates are specified for each application on the label. Labeled use rates must be followed for maximum effectiveness and safety. Always read the label and do not exceed the labeled use rate for fogging insecticides. Most fogging insecticides have indoor fogging use rates of 0.5 to 1.0 ounce of insecticide for each 1,000 cubic feet of air space fogged. As an example, a room 100 ft. by 200 ft. with a 20 ft. ceiling height equals 400,000 cubic feet of air space. At a use rate of 1.0 ounce per 1,000 cubic feet, would require 400 ounces of insecticide or 3.1 gallons (400 divided by 128 ounce per gallon = 3.1 gallons). Since a room is almost always occupied by stored materials, equipment, etc., you will need to subtract for the air space occupied by materials in the room. Generally, you can subtract 15% for occupancy by material in the area fogged. 3.1 gallons less 15% = 2.6 gallons of insecticide is the maximum use rate for the 100 ft. by 200 ft. by 20 ft. room. Generally, its best to apply the maximum use rate with fogging insecticides. The maximum use rate provides the best fog coverage and thus the best penetration into small and hard to reach surfaces.

Call Entech (504-469—6541) for additional information or clarification. Entech has a PowerPoint training program “Use of Fogging Insecticides in Food processing & Storage Facilities” that is available at no charge.